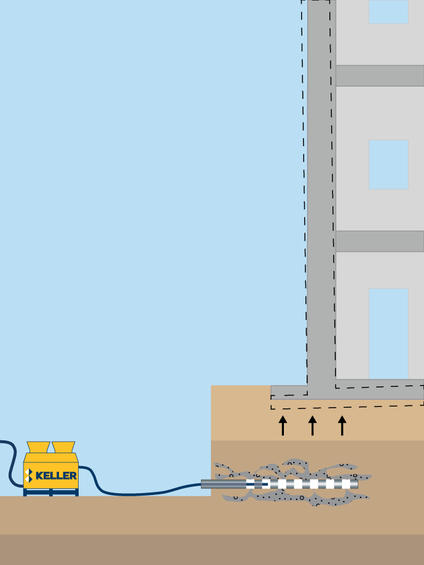

Compensation grouting, or fracture grouting, is the injection of a cement slurry grout, hydrofracturing soil, and creating lenses. The lenses compact the surrounding soil and lift the overlying soil and structures.

Common uses

Process

Fracture grouting, or compensation grouting, hydrofractures in situ soil using cement slurry grout. A sleeve port pipe is grouted into a pre-drilled hole beneath a structure. The grout is injected under pressure at strategic locations through the ports in the pipe.

Once the hydrofracture pressure of the soil is exceeded, fractures open in the soil and are immediately expanded by the influx of grout. This process results in a controlled heave of the overlying soils and structures.

Specialist contacts

- T:

- 973-417-1667

Lucian's areas of specialization include ground modification using various grouting techniques and grout components, and construction dewatering using wells, wellpoints and ejector systems. Major projects of note include the Second Avenue, East Side Access and Number 7 Line Extension transportation system upgrades in Manhattan, NY; low mobility grouting for remediation of a 300-foot diameter, 320-foot-deep gypsum stack sinkhole in Florida; and a number of rehabilitation projects at the World Trade Center site.

- T:

- 973-897-4101

Max's role includes the oversight and management of Keller's designing, estimating, procuring, and QA/QC of specialty grouting jobs with scopes of work including jet grouting, compaction grouting, rock grouting, and permeation grouting (e.g., cement, chemical). This includes the most complex of geotechnical projects which include a wide array of applications including temporary and permanent underpinning, bathtub excavations, tunneling, liquefaction mitigation, foundations, support of excavation, and hydraulic barriers.

Advantages

Quality assurance

Keller can provide complete solutions which combine fracture grouting with real-time monitoring of affected structures.

Extensive experience has allowed us to develop advanced drilling and computerized grouting systems integrating the grouting injection process and real-time monitoring. Grout injection data is plotted against time and summarized in three-dimensional plots and reports.