Wick drains, or prefabricated vertical drains (PVDs), are prefabricated geotextile filter-wrapped plastic strips with molded channels. These act as drainage paths to take pore water out of soft compressible soil so it consolidates faster, often from decades to months.

Common uses

Process

Wick drains, or PVDs, consist of a prefabricated strip ideal for water transportation. The flexible core is typically manufactured of polypropylene, and both sides have grooves allowing water to flow unimpeded. The core is wrapped in a strong and durable geotextile filter fabric with excellent filtration properties, allowing free access of pore water into the drain. This also prevents piping of fines from adjacent soils without clogging.

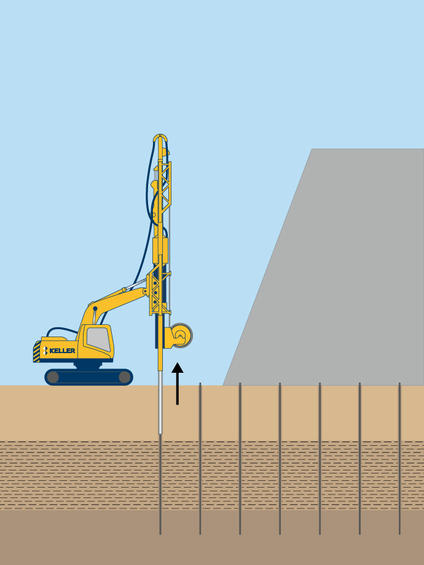

The drain is fed down through a hollow mandrel mounted on an excavator or crane mast, connected to an expendable anchor plate at the bottom. A vibratory hammer or static method inserts the mandrel to design depth. It’s then removed, leaving the wick drain in place. The wick drain is then cut at the ground surface, a new anchor plate is connected, and the mandrel is moved to the next location. A pattern of installed vertical wick drains provides short drainage paths for pore water, accelerating the consolidation process and the construction schedule.

Specialist contact

- T:

- 303-801-8068

Logan has over 13 years of expertise in the geotechnical construction industry, managing and executing complex projects across North America. His career has been dedicated to delivering innovative and cost-effective solutions for some of the most challenging infrastructure projects, ensuring safety, quality, and sustainability at every stage.

Advantages

Quality assurance

We ensure quality through the following:

- Automated data acquisition to record all installation parameters

- Trial area monitoring to prove design assumptions

- Surcharge monitoring