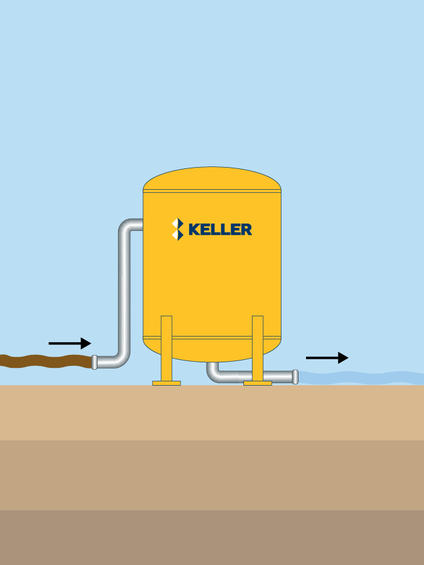

Groundwater or construction water encountered at job sites is often contaminated and must be processed before being discharged to local surface waters, storm sewers, or sanitary sewers. Keller offers groundwater treatment services to treat water for discharge while keeping sites dry and complying with permits and local regulations.

Common uses

Process

Potential sources of contamination can be historic such as volatile organics, metals, and pesticides that leached into the groundwater from former industrial, agricultural, or landfill areas. They can also stem from job-related activities. Construction water, for example, is often laden with silts, bentonite, or cement or exceeds allowable pH levels.

Keller provides various treatment solutions to fit a variety of applications and requirements because every site is different. We can review site environmental assessments and groundwater analytical reports to design a groundwater treatment system specifically for your needs. Our solutions can be turn-key with full operation and maintenance or system rentals with Keller technical support as needed.

Treatment solutions

- Suspended solids and turbidity control

- pH control and adjustment

- Metals precipitation

- Carbon absorption

- Media absorption (resins, organo clays, etc.)

- Oil/water separation

- Chemical injection systems

Equipment rentals

- Pumps

- Media vessels

- Bag filters

- Sand filters

- Clarifiers

- Oil/water separators

- Chemical injection systems

- Monitoring equipment

We can bundle our geotechnical, dewatering, and groundwater treatment expertise to provide a one-stop approach for projects to progress more efficiently.

Specialist contact

Robert Marra | Area Manager | 973-441-0042

John Balla | Senior Project Manager | 862-396-0391

Leigh Finn | Project Manager | 973-400-3664