Cutter Soil Mixing (CSM) enhances the engineering properties of soils and reinforces soil masses by mechanically mixing the in situ soils with a binder slurry, typically comprising either cement or bentonite slurry or a combination of the two.

Common uses

Process

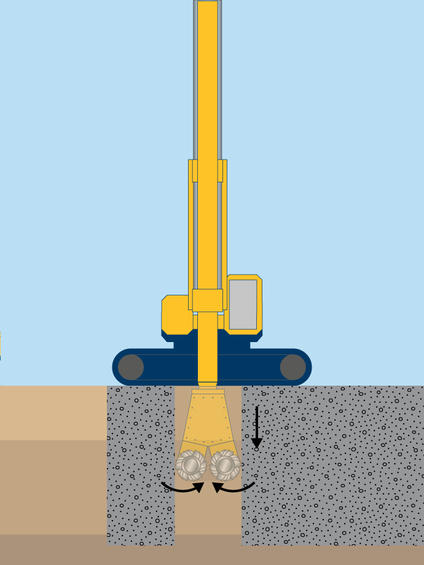

Cutter Soil Mixing (CSM) is a specialized deep mixing technique used in almost any soil type. The process incorporates cutter wheels, rotating about horizontal axes, and mounted on the end of a Kelly Bar, cutting their way into the soils to form a panel of improved soil that is rectangular in plan. As the cutter head advances, binder slurry is pumped through a nozzle between the wheels and mixed with the in-situ soils. The action of the cutter teeth and cutting fins, combined with the shear plates situated just above the wheels, serves to develop a thoroughly mixed soil mass. Adding binder on the withdrawal stroke, combined with a high rotation speed of the cutter wheels, blends the soils and slurry further and creates a well-mixed in situ product.

Cutter Soil Mixing creates strengthened and stiffened individual soilcrete elements, commonly called panels. Treatment is possible at up to 50m depths using large base carriers; however, typical panel depths are 25 to 35m. Pre-drilling can be used to improve productivity in very dense soils or soft rock. The ease of the process is contingent on soil type, strength, water content, plasticity, and texture.