Interlocking pipe piles consist of tightly interlocked pipe piles using an innovative mechanical “ball-and-socket” type connector welded to the full length of the pipe to create a continuous watertight wall that can be temporary or permanent.

Common uses

Process

Unlike other excavation support techniques, such as sheet piling and secant pile walls, interlocking pipe piles can be installed through bouldery ground conditions.

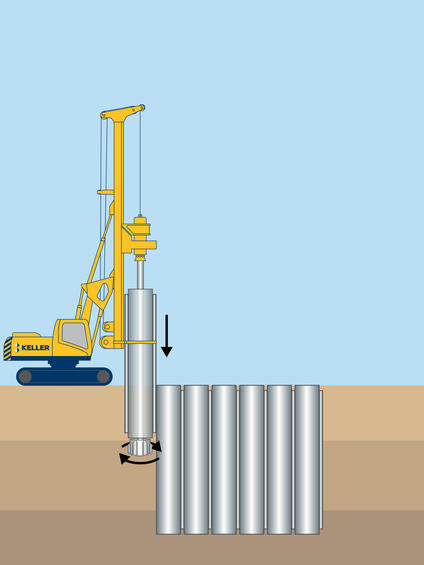

A pile guide/template is laid out on the surface to ensure verticality during installation. Interlocking pipe piles are installed using rotary percussion reverse circulation drilling techniques, air/water flush, and a down-the-hole hammer to handle boulders and obstructions.

Accurate determination of top-of-rock elevations allows the pile assembly to be prefabricated off-site. This saves time in the overall installation schedule and is also advantageous where the working area is limited. The pipe pile assembly, complete with an interlock, is advanced to design depth in a single pass and can be readily embedded into the sound rock. Grouting is performed inside the pipe and the annulus space to complete the cut-off.

Advantages

Quality assurance

A dedicated full-time technician is assigned to perform quality control and quality assurance. This can include pre- and post-wall installation pump tests, pile verticality checks during installation, production pile drill logs and grout logs, and permeability testing to confirm the adequacy of the cut-off wall.