The cased CFA pile is a continuous pile drilling and installation technique with low noise and no vibration. It is ideal for excavations requiring shoring systems abutting existing buildings within built-up areas with weak soil conditions and high groundwater levels.

Common uses

Process

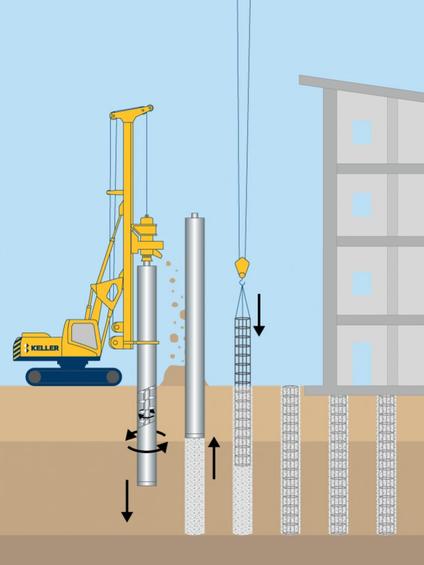

Cased CFA piles are constructed by rotating a hollow stem continuous flight auger within a temporary casing into the soil to a designated depth. The double rotary drive units for the auger and casing rotate in opposite directions, simultaneously drilling them into the ground. This allows for faster continuous drilling while the casing helps to keep the pile vertical, which is important for applications such as secant pile retaining walls. Concrete or grout is pumped through the hollow stem, maintaining static head pressure, to fill the pile drill hole as the auger and casing are slowly removed. Upon completion, the reinforcing (pipe/I-beam/cage) is installed while the concrete/grout mix is fluid.

We have extensive experience working on challenging sites where access is difficult or compromised and existing infrastructure, such as underground services and transport links, is present.

Advantages

Quality assurance

Close control of the installation process is essential to ensure the highest quality pile construction.

All Keller CFA rigs are equipped with sensitive state-of-the-art instrumentation that monitors all aspects of CFA piling, including pile depth, auger rotation, penetration rate, concreting pressure, extraction rate, and over-break. The instrumentation produces a quality control construction record for each pile, including element identification, date, time, and operator details.