High mobility (cement slurry) grouting, or cement or rock grouting, is usually done in fissured rock to reduce water flow along the joints and discontinuities in the rock. Occasionally, cement grouts are injected into the void space within coarse granular soils.

Common uses

Process

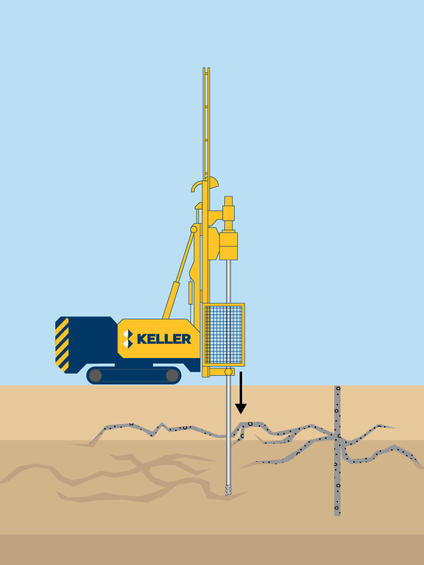

High mobility grouting fills pores in granular soil or voids in rock/soil with flowable particulate grouts. The grout particle and void sizes must be appropriately matched to allow the cement grout to permeate. Depending on the conditions, Portland cement or microfine cement grout is injected under pressure at strategic locations through a single port or multiple port pipes. The grouted mass has increased strength, stiffness, and reduced permeability.

Cement grouting can offer an economic advantage for underpinning applications over alternative approaches such as removal and replacement or piling. It can be performed where access is complex and space is limited. Since the effectiveness of cement grouting is independent of structural connections, this technique is readily adaptable to existing foundations and can typically be accomplished without disrupting normal facility operations.

Specialist contacts

- T:

- 973-417-1667

Lucian's areas of specialization include ground modification using various grouting techniques and grout components, and construction dewatering using wells, wellpoints and ejector systems. Major projects of note include the Second Avenue, East Side Access and Number 7 Line Extension transportation system upgrades in Manhattan, NY; low mobility grouting for remediation of a 300-foot diameter, 320-foot-deep gypsum stack sinkhole in Florida; and a number of rehabilitation projects at the World Trade Center site.

- T:

- 973-897-4101

Max's role includes the oversight and management of Keller's designing, estimating, procuring, and QA/QC of specialty grouting jobs with scopes of work including jet grouting, compaction grouting, rock grouting, and permeation grouting (e.g., cement, chemical). This includes the most complex of geotechnical projects which include a wide array of applications including temporary and permanent underpinning, bathtub excavations, tunneling, liquefaction mitigation, foundations, support of excavation, and hydraulic barriers.

Advantages

Quality assurance

Keller has developed proprietary equipment and software (iGroutTM) to allow real-time monitoring of all parameters during the cement grouting process. The operator can adjust the parameters (such as mix type, flow rate, pressure, and volume limits) based on the real-time acquisition of drilling and grouting data while simultaneously monitoring for any movements or deflections of the ground or nearby structures. Data collected during drilling and grouting is recorded on a server that produces grouting reports and CAD drawings depicting a visual representation of the completed work. This advanced monitoring and control system increases the accuracy, efficiency, and quality control of cement grouting.