Soil nailing uses grouted, tension-resisting steel elements (nails) to reinforce in situ soils and create a gravity retaining wall for permanent or temporary excavation support.

Common uses

Process

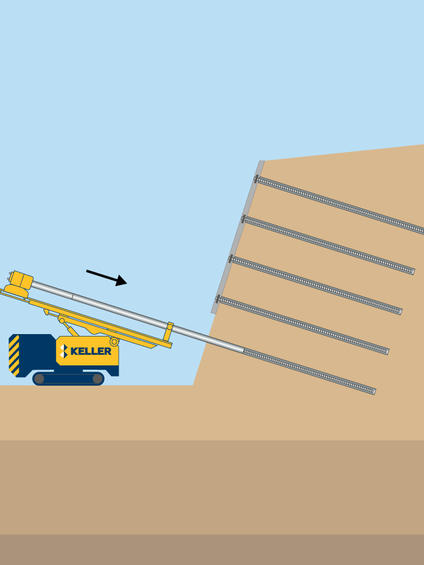

Soil nail walls are generally constructed from the top down. Typically, the soil is excavated in three to six feet deep stages. After each excavation stage, near-horizontal holes are drilled into the exposed face at typically three to six-foot centers. Tension-resisting steel bars are inserted into the holes and grouted in place. A drainage system is installed on the exposed face, followed by the application of reinforced shotcrete wall facing. Precast face panels can also be used. Bearing plates are fixed to the heads of the soil nails.

This installation process is repeated until the design wall depth is reached. The finished soil nails produce a zone of reinforced ground.

Advantages

Quality assurance

Keller has installed and developed soil nailing techniques for years. We use specialized equipment and experienced crews and employ strict quality control measures to ensure uniform and consistent results. We have used extensive 3D modeling to avoid conflicts between soil nails and other earth retention systems and to avoid buried utilities.