Vibro piers® (also known as aggregate piers) are stiff aggregate piers constructed to reinforce fine-grained soils. Keller developed this technique, and it has since been used on thousands of projects.

Common uses

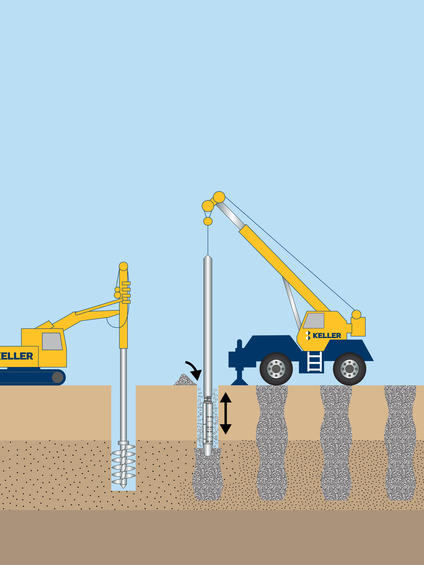

Process

Vibro piers® or aggregate piers are typically installed to intermediate depths of 5 to 20 feet to support new loads. Suited for light to heavy loads on large or small projects, vibro piers are quick to install and very effective at reinforcing the surrounding soil.

Typical construction begins with pre-drilling the pier location to create a full-depth hole with a diameter equal to the final pier design diameter. In soils that cave or collapse, a bottom-feed vibrator can be used. The down-hole vibrator is lowered vertically to the planned tip of the pier by a standard crane or rig built for this technique. Aggregate (new crushed stone or recycled concrete) is then added to the hole or through the bottom-feed system and is compacted in lifts by repeated penetrations with the vibrator. The vibratory energy densifies the aggregate and any surrounding granular soil. The high modulus pier reinforces the treatment zone, increasing bearing capacity and shear resistance and reducing settlement from new loads.

For seismic applications, vibro piers can effectively reduce dynamic settlement. If loose granular layers are present, the process is a very effective densification technique, reducing the liquefaction potential.

3D animation

Advantages

Quality assurance

The vibro equipment we use is designed and manufactured by our in-house equipment manufacturer exclusively for use by Keller.

Quality control and quality assurance plans are essential to each vibro pier program and ensure the foundation system meets the project’s needs. Quality control includes procedural inspection and documentation of the work activity, pre-drill diameter and depth, time and energy parameters, aggregate quantity, and treatment depth. The performance of the vibro pier system is verified by a vibro pier modulus test to confirm the pier modulus used in the design.