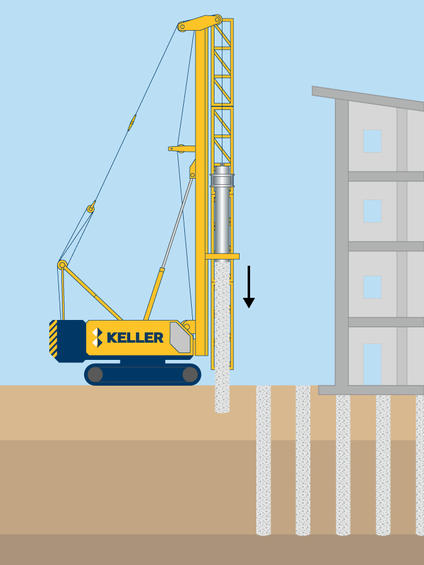

Driven piles are deep foundation elements installed using impact or vibration hammers to a design depth or resistance.

Common uses

Process

In addition to structural support, driven piles provide lateral support for retaining walls. The piles are advanced to design tip depth or nominal resistance using an impact or vibration hammer and are typically installed in groups and tied into a pile cap. When penetration of dense soils is necessary, pre-drilling is required for the pile to achieve the specified design depth. Driven piles can be made of timber, pre-cast concrete, steel H-piles, steel sheet piles, or pipe piles.

Piles can be installed as a single length or spliced for extremely deep piles. Driven piles do not create spoil, and since no curing time is required, they can be installed in sequence, speeding up the overall production time. The completed pile element resists compressive and lateral loads and uplift forces.

Advantages

Quality assurance

Keller has access to an extensive selection of pile sizes to ensure an optimum design solution and can draw on extensive experience and resources to ensure successful project delivery. We use the most up-to-date, enclosed hydraulic hammers, which minimize noise disturbance.