With the increasing severity of weather events and urbanization leading to higher water flows, sewer system improvements are consistently underway to increase capacity. In West Lynn, the installation of a 54-inch force main was underway when Keller was contacted to formulate a ground improvement solution to allow for the safe installation.

The project

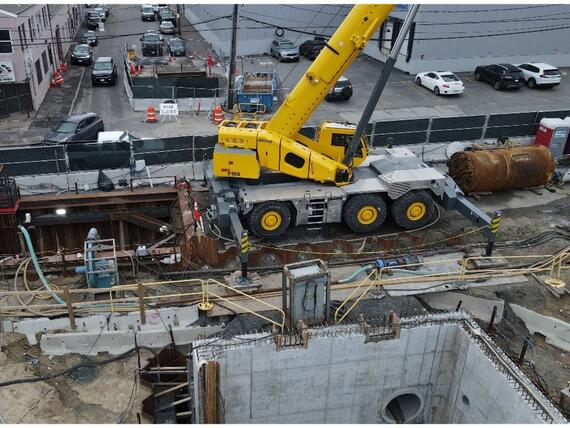

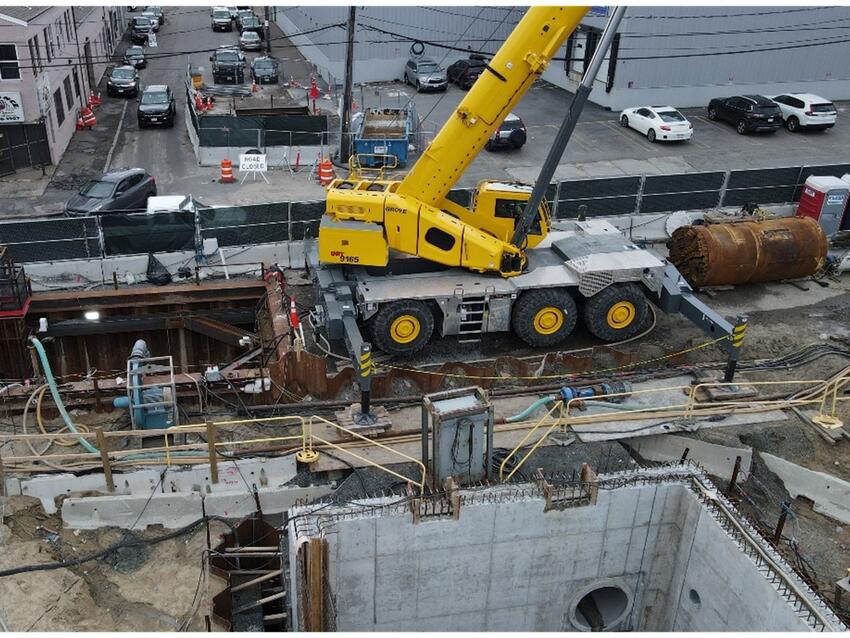

The project included microtunneling along the Commercial Street Tunnel, where a 66-inch-diameter steel casing pipe was to be advanced 931 ft from the launch shaft to the receiving shaft. The shafts were rectangular excavations, supported by sheet pile earth retention, with subgrade located approximately 24 ft below the static groundwater table. The soils along the tunnel alignment included Boston Blue Clay Crust and Boston Blue Clay overlain by a layer of undifferentiated sands.

The site presented numerous challenges, including multiple utilities within the work zone, limited staging areas, and soft clays and groundwater within the tunneling zone. The ‘break-in’ and ‘break-out’ areas of the launch shafts required ground improvement to prevent groundwater flow into the excavation. Selection of the ground improvement method required consideration of the multiple underground utilities within the work zone.

Keller was asked to propose and design a solution to mitigate the risks of ground loss and water inflows into the excavations by stabilizing the ground outside the sheet piles before the micro tunneling operation. Keller installed break-in/out blocks via jet grouting at the receiving and launch shafts, respectively. Crews implemented vacuum trucks to manage spoils in the small work areas, which minimized the need for equipment and stockpiles on site.