When completed and fully operational, Muskrat Falls will be the second-largest hydroelectric facility in Newfoundland and Labrador.

The project

Muskrat Falls Generating Station, owned and operated by Nalcor Energy, spans the Lower Churchill River and forms the reservoir that is the source of power for the plant. The 824-MW facility consists of two primary dam sections, designated North and South, separated by a powerhouse structure containing four generator units. The facility also includes a 5-bay spillway.

The South and North dam structures, 820 ft (220 m) and 450 m (1475 ft) in length respectively, are founded on very hard, fissured rock. Remediation of the rock fissures was required to ensure overall dam stability once the station became operational.

The challenge

For Bernard Pennecon, the main contractor, the primary challenge lay in the timely and successful completion of the deeply fissured rock in order to maintain the overall project schedule for full dam completion.

Keller’s faced two main challenges: higher than usual grouting pressures required by the design put additional stress on the equipment and resolving lower than usual production rates due to the physical and logistical challenges of working within the tunnel and accommodating split spacing.

The solution

For both dam sections, high mobility curtain grouting of the fissures was used as the rock remediation method, with the Grout Intensity Number (GIN) specified as the method to determine completion of grouting at any location. The GIN value was determined early in the project by the Site Engineer and derived as a product of grout volume and grout pressure. GIN values typically vary with grouting depth.

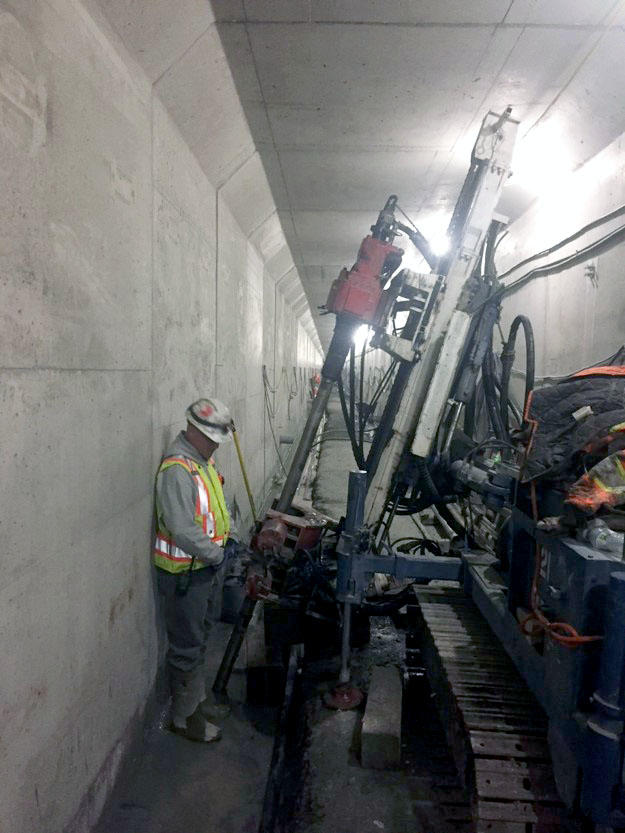

For the South Dam, which was completed in 2016, grouting operations were performed directly from the top of rock ahead of construction of the dam’s rock-filled earthen embankment. However, for the North Dam, which was designed and built as a roller-compacted concrete structure, grouting was performed from an 8.2-ft (2.5-m) wide, 9.8 to 11.8-ft (3 to 3.6-m) high horizontal drainage tunnel within the dam structure. Space limitations allowed for just the electric drill rig, hoses, and grout distribution manifold inside the tunnel. The grout batch plant and additional components, such as the generator, water storage, and pump, were located outside on the downstream side of the dam.

The single-line grout curtain was completed in a primary/secondary sequence using an electric drill rig with a water hammer. Primary locations were spaced 80 ft (24 m) apart and split-spaced by the secondaries. Grouting was conducted in the upper 50 to 65 ft (15 to20 m) of the rock, which was approximately 100 ft (30m) from working grade. Real-time monitoring using an automated Data System enabled Keller to refine the grouting parameters as required. The North Dam grouting work was completed in early 2019, with all four generator units slated to be fully operational by Fall 2021.