Keller improved surrounding soil to facilitate the tunnel construction of the Eglinton Crosstown light rail line.

The project

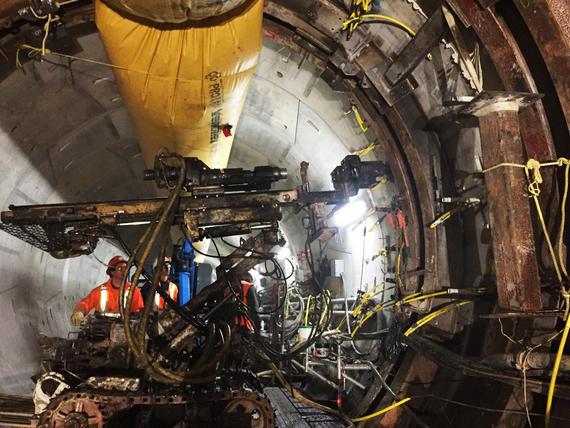

The Eglinton Crosstown light rail line was under construction in Toronto, Ontario, which required cross passages to be constructed at various locations between the Westbound and Eastbound tunnels for servicing and emergency purposes when the line became operational.

The challenge

The presence of silty clay soil at two of the cross passages (no. 11 & 12) posed a problem for conventional de-watering methods. Soil stabilization was required to temporarily improve the soil prior to hand mining operations from inside of the existing tunnels to create the cross passages tunnel.

The solution

Keller performed permeation grouting at CP-11 & CP-12. Multiple port steel sleeve pipes were installed to create a canopy from both the Westbound and Eastbound tunnels. In addition, the excavated face was reinforced with fiberglass rebar affixed to PVC multiple port sleeve pipes (MPSP). MasterRoc MP325 grout was injected under pressure with a double packer system through ports on the sleeve pipes. The grouted zone showed increased strength and reduced permeability within days of grout injection. Keller worked 24 hours a day to meet the project schedule and allow for the cross-passage construction to continue.